Engineering - Mechanical Equipment: pressure vessel, storage tank, heat exchanger & stack design

G&B offers a wide range of engineering services to assist you in running your projects, optimising cost (without increasing your initial investment) and keeping your delivery dates. The company’s specialised teams can assist you during the full design phase of your project.

The company uses the best and latest software and hardware in the market to ensure best results in your projects and our QA department controls all the project’s tasks to avoid a badly resourced management. Our experience with the internal procedures could assist you with your effort of keeping your project cost controlled and on schedule.

The Group’s companies are located in UK, Spain, USA and Mexico and are well accustomed to operating internationally and consequently, the group’s engineers are familiar with the different international standards, as well as with the internal codes of main industrial countries. G&B draws on this extensive expertise when undertaking international projects.

G&B specialises in the mechanical design and production of GA & fabrication CAD drawings of pressure vessels, storage tanks, heat exchangers and stacks design, in the following industries: Petrochemical (offshore and onshore), chemical, power generation, nuclear, pharmaceutical, food, refrigeration, heating and ventilation, etc.

G&B specialises in the mechanical design and production of GA & fabrication CAD drawings of pressure vessels, storage tanks, heat exchangers and stacks design, in the following industries: Petrochemical (offshore and onshore), chemical, power generation, nuclear, pharmaceutical, food, refrigeration, heating and ventilation, etc.

We can design to the following codes:

- Pressure Vessels: ASME VIII DIV. I & II, PD 5500, EN 13445 & Pressure Equipment Directive (PED).

- Shell & Tubes Heat Exchangers: TEMA, ASME VIII DIV I, PD 5500 & PED.

- Air Cooled Heat Exchangers (Fin-Fan): API 661 (including header boxes design).

- Storage Tanks: API 650, API 620, BS EN 14015 and Rectangular Tanks to GEP.

- Stacks (Chimneys): BS 4076 and GEP.

- The above also under the requirements of DnV and Lloyds.

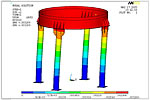

- Specialised Calculations: fatigue assessment, thermal/mechanical stress calculations, wind loads & vibrations, seismic loads, liquid sloshing effects, effect of piping external loads on nozzles/shells, secondary & discontinuity stresses, creep and creep-fatigue effect calculations and any associated Finite Element Analysis (FEA). Calculations are performed using the best available industry software and in-house spreadsheets/MathCad.

Code Design software: Finglow, PVElite, spreadsheets/MathCad

Drafting software: AutoCad, SolidWorks

FEA software: see the FEA section in this Engineering section.

info@gbengineeringservices.com

info@gbengineeringservices.com +44 (0) 20-83686117

+44 (0) 20-83686117